Nature does wonders! Who would have thought that something within the intestines of pigs called heparin could be used to make drugs being used in modern operating rooms in all hospitals?

Heparin is a type of sugar that can prevent blood from clotting. It is commonly used in operating rooms to prevent conditions caused by blood clots.

Well, nature gave us the clue, but humans may collect the raw materials carelessly, and contaminated intestines may lead to unsafe heparin. On top of that, there are many religious concerns with medicines made directly from pig organs.

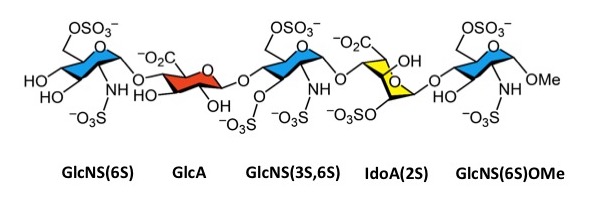

Therefore, scientists looked closer and identified a structure with only five sugar units in the whole heparin as the key component that inhibits blood clotting, the rest of heparin and the pig intestine are unnecessary for drug preparation, only added potential side effects. In this case, a synthesized chemical compound composed of the crucial pentasaccharide structure proved a much better medical solution for the situation.

|

| Figure 1: The key sugar molecules to prevent blood clotting |

Actually, the pentasaccharide drug Fondaparinux was successfully introduced in 2002. It was great, no more unwanted side effects in the operating rooms, except, the cost is too high and unaffordable to lots of people.

Hence, when Dr. Shang-Cheng Hung’s team announced their method of making Fondaparinux with almost half of the processing steps: from 55 steps down to 32 steps; it made a significant impact on the pharmaceutical industry.

|

| Figure 2: Team members from left: Shang-Cheng Hung, Teng-Yi Huang, Cheng-Po Cheng, Zheng-Hao Tzeng, Cheng-Hsiu Chang |

Dr. Hung has spent a long time in the study of heparin. As a chemist specializing in sugar synthesis, he invented a ‘one-pot protection’ strategy to prepare carbohydrates. Carbohydrates are extremely hard to synthesize, months or sometimes years of effort are often spent in making one compound, and the yield is low. Hung’s creative method is extended into making Fondaparinux. This way, they can avoid many intermittent tedious steps and time-consuming purifications. Simply put, they reduced the workload in the linear procedures.

Their achievement has won them the 2016 National Innovation Award presented by the Institute for Biotechnology and Medicine Industry (IBMI).

Currently, the team is working on the mass production strategy. Technology transfer is undergoing and promising. Congratulations to the Shang-Cheng Hung’s team!

|

| Figure 3: Aiming production of Fondaparinux in one big pot |